Learn how to evaluate Chinese CNC manufacturers, avoid red flags, and make smart sourcing decisions for quality equipment.

The Chinese CNC Manufacturing Landscape

China produces more CNC equipment than any other country. This means tremendous variety—but also tremendous variation in quality. Understanding the landscape helps you make better sourcing decisions.

Major Manufacturing Regions

- Jinan, Shandong: Heavy concentration of CNC router manufacturers

- Guangzhou/Shenzhen: Electronics and precision equipment

- Hangzhou/Ningbo: Machine tools and components

- Dalian: Heavy industrial equipment

Types of Suppliers You'll Encounter

- Actual manufacturers: Companies that design and build machines in their own factories

- Assemblers: Companies that combine components from various sources

- Trading companies: Middlemen who source from multiple factories

- OEM/ODM suppliers: Build machines to customer specifications or allow branding

Where to Find Chinese CNC Manufacturers

Online Marketplaces

- Alibaba: Largest platform, wide range of suppliers and quality levels

- Made-in-China: Similar platform with verified manufacturers

- GlobalSources: More focus on verified, larger suppliers

Trade Shows

- CIMT (China International Machine Tool Show): Major industry event

- CCMT (China CNC Machine Tool Fair): Focused on CNC equipment

- Canton Fair: General manufacturing with machinery section

Industry Connections

- Referrals from other equipment owners

- Industry forums and groups

- Equipment dealers with established supplier relationships

Red Flags When Evaluating Manufacturers

Watch for these warning signs:

Pricing That's Too Good

If a quote is dramatically lower than others for the same specifications, something is being cut. Usually it's component quality, which you won't discover until the machine fails.

Vague Specifications

Legitimate manufacturers can tell you exactly what components they use. "High quality spindle" without brand or specifications is a red flag.

No Factory Access

Reputable manufacturers welcome video calls showing production. If they won't show you the factory, ask why.

Communication Problems

If basic questions get confused or ignored before you buy, imagine trying to resolve problems after purchase.

No US Customer References

Ask specifically for US customers you can contact. Machines that work well in controlled factory demos may struggle in real production environments.

Missing Certifications

CE marking, and ideally UL certification for US, indicate the manufacturer follows safety standards. Absence suggests cost-cutting on safety.

Essential Questions to Ask Manufacturers

About Components

- What brand and model spindle is used?

- What are the linear rail specifications and manufacturer?

- What ball screws are installed (grade, preload, manufacturer)?

- What controller system is included?

- What brand and type of stepper motors or servos?

About Quality

- What testing is performed before shipping?

- Can you provide test cut videos or accuracy reports?

- What's your defect rate/return rate?

- How do you handle quality issues discovered after delivery?

About Service

- What warranty is offered?

- How do you support customers in the US?

- What's the typical response time for technical questions?

- How quickly can replacement parts ship?

About Logistics

- How is the machine packaged for ocean shipping?

- What documentation is provided for customs?

- Do you have experience shipping to the US?

- What's included versus what's additional cost?

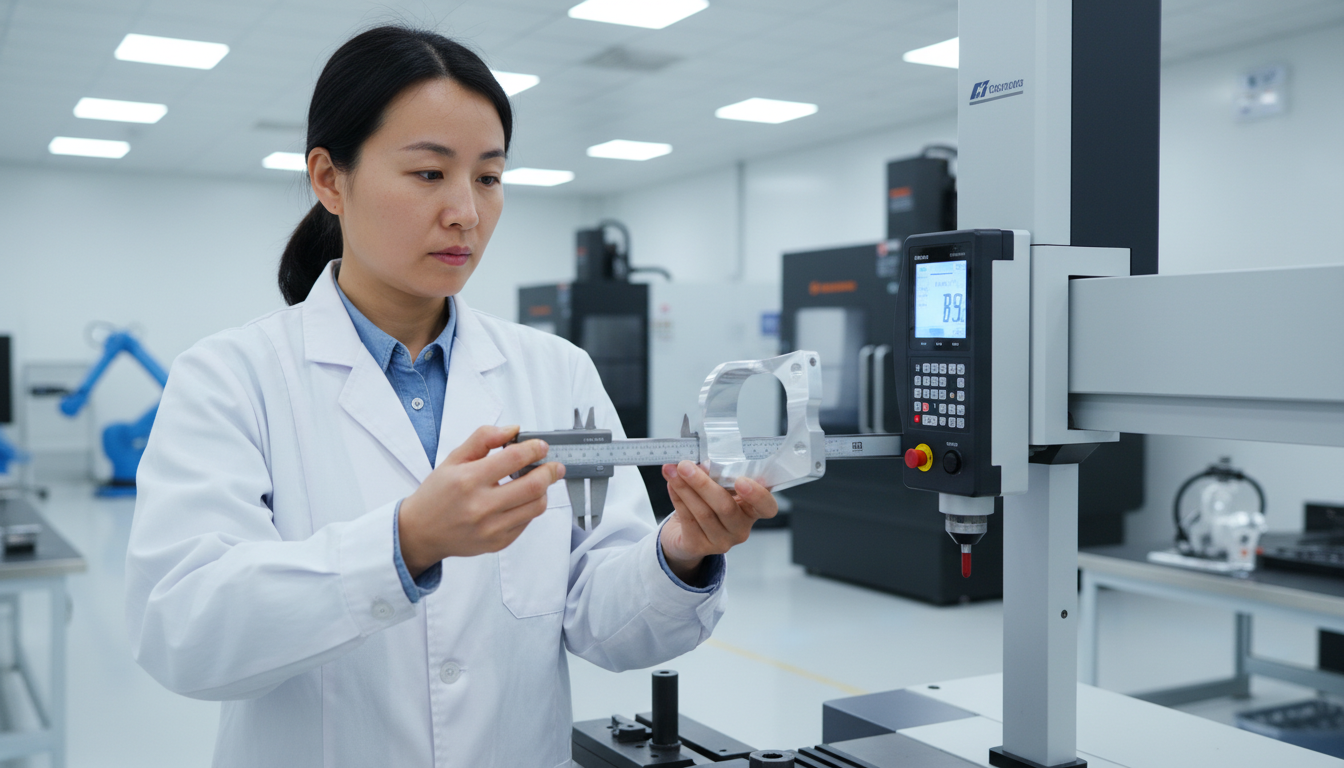

Quality Verification Steps

Before committing to a purchase:

Request Detailed Documentation

- Complete specification sheets with actual component details

- Assembly and wiring diagrams

- Quality control inspection reports

- User manuals (in English)

Video Verification

- Live video call showing your machine being built or tested

- Test cutting videos with your specified materials

- Factory tour showing production processes

Third-Party Inspection

- Hire an inspection service to visit the factory

- Have them verify specifications match what was promised

- Document condition before shipping

Sample Parts

- Request sample cuts from the actual machine

- Verify accuracy and surface finish meet your requirements

The Logistics Challenge

Even with a good machine from a reliable manufacturer, getting it to your facility is complicated:

Freight Forwarding

- Booking container space or LCL (less than container load)

- Marine insurance for transit

- Port handling and documentation

Customs Clearance

- HS codes and duty rates for CNC equipment

- Required documentation (commercial invoice, packing list, bill of lading)

- Potential inspections or holds

Final Mile Delivery

- Transporting from port to your facility

- Liftgate and forklift requirements for heavy machines

- Scheduling to ensure someone can receive delivery

Unboxing and Installation

- Removing shipping crating and protective materials

- Moving machine to final position

- Leveling and assembly of shipped-separate components

- Electrical hookup and testing

An Alternative Approach

All of this research, verification, negotiation, and logistics management takes significant time and carries real risk. That's why many US businesses choose to work with domestic equipment dealers instead.

What Dealers Provide

- Established relationships with vetted manufacturers

- Pre-purchase quality verification

- Complete logistics handling

- Professional installation and setup

- Training for your operators

- Ongoing technical support

- Local parts availability

The Trade-Off

You'll pay more than direct import pricing. What you're buying is:

- Risk reduction

- Time savings

- Professional support

- Insurance against problems

Make an Informed Decision

Whether you source directly or work with a dealer, understanding Chinese manufacturing helps you ask better questions and evaluate options more effectively.

Contact us to discuss your equipment needs. We can share insights from our sourcing experience and help you determine the best path for your situation. Browse our current inventory to see pre-vetted equipment available for delivery.

Ready to get started?

Browse our equipment inventory or get in touch with our team for expert advice on your next project.